By working differently you can generate benefits in your supply chain. Asking the right questions is the key.

One supply chain goal is consistent in any type of economy: reduce costs. Faced with this objective, ask the first question is always, “Who can do the work cheaper?” While procurement initiatives can improve profitability, requesting new rates in an inefficient design will return only limited results. Perhaps the better question is “How can I work differently?”

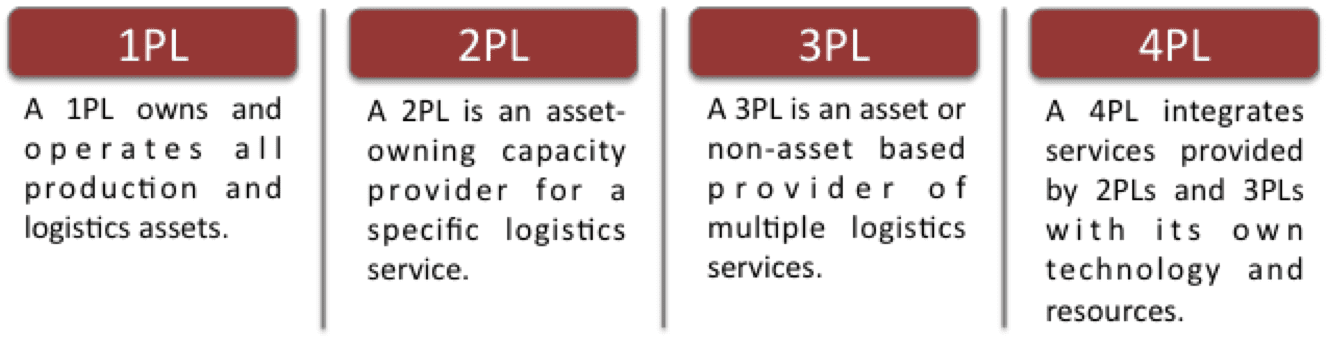

Companies have quickly matured from owning their own logistics assets and managing all logistic processes in-house to combining a variety of 2PL and 3PL regionally-based solutions to minimize complexity and achieve cost and time savings. With so many internal and external parties involved, shop evaluating your logistics strategy can be a daunting task.

1 What is your logistics strategy today?

People, process, and systems constitute the majority of supply chain costs. Step one is to find out where your strategy is today on the continuum below.

2 How many points of contact do you want to manage?

Resist the urge to sub-optimize. Breaking the chain into smaller pieces and finding suppliers for each piece increases complexity. Separate your supply chain into workflows by regional sources and destination markets and find a supplier to manage end to end. Decreasing total logistics time and cost should be the focus rather than reducing costs in one segment which may increase costs in another.

3 Do you want to own your logistics technology?

Over the years, you have pushed your logistics asset costs to suppliers, why should technology be any different? Transfer your fixed logistics systems costs to a variable cost per unit. As order volume drops, so will your costs. Logistics suppliers can amortize systems costs over multiple customers, providing you with more functionality at a cheaper cost.

4 How much logistics competency do you want to maintain?

Moving products from points of production to consumption will always be a critical part of your business but one you can manage as a variable cost. Like with technology, push costs for competence development to a leading logistics provider. This also allows you to focus more resources on your core business.

5 What do you want your logistics strategy to be in the future?

Considering your answers to the previous questions, what do you want your strategy to be in the future? Once you choose the strategy, identify potential supply chain providers specializing in that solution with your type of cargo. Focus on providers who have been proven supply chain partners in the past and stakeholders in your future success.